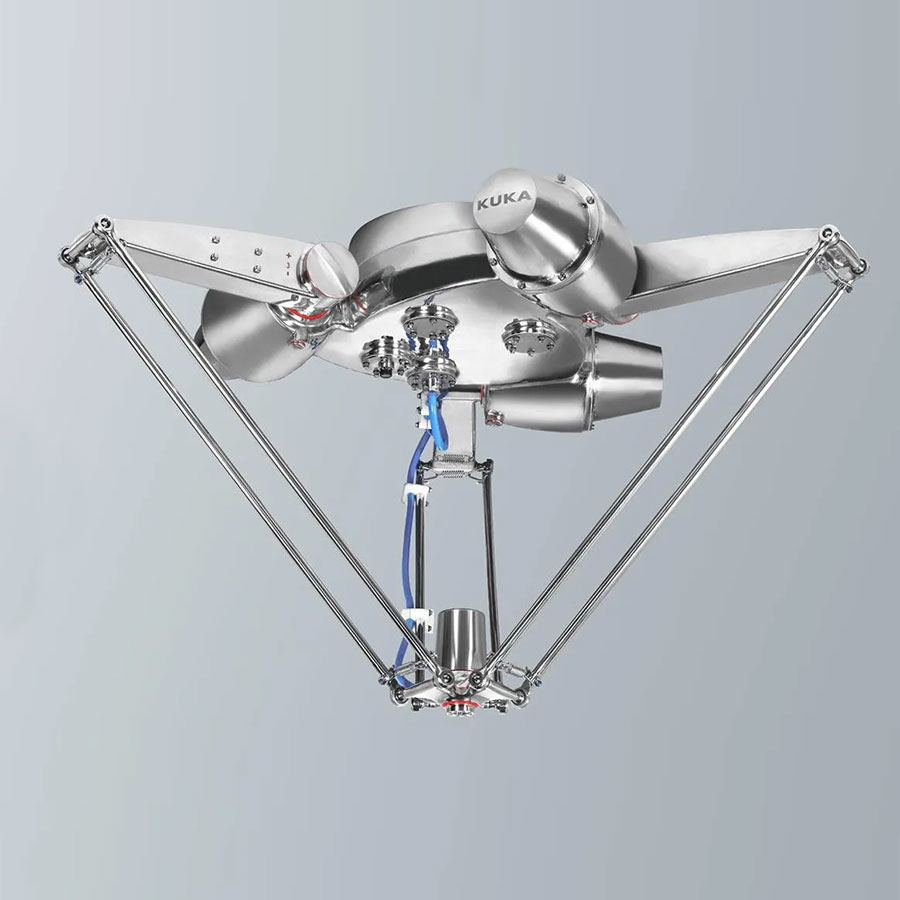

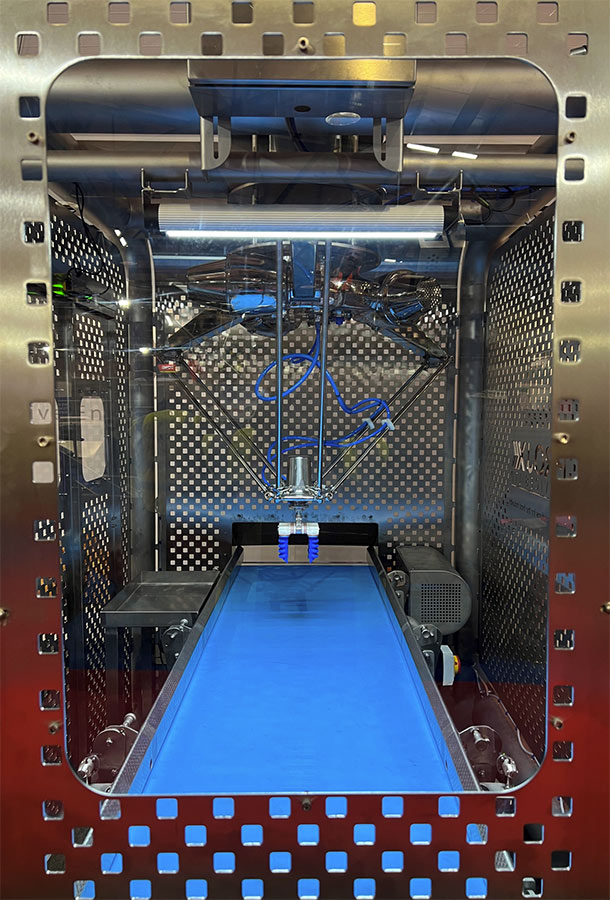

KUKA DELTA robots are designed for use in highly sensitive conditions. Thanks to its stainless steel body, the DELTA robot is ideally equipped for hygienically sensitive areas, such as direct contact with food, medicines or electronic components.

Industrial robots are an essential element within today’s factory environment, even more so within the factory of the future. The demand for industrial robots stems from the need for versatile, intelligent machines able to perform repetitive tasks cost-effectively with a wide range of motion whilst maintaining quality consistencies and reduced cycle time. The delta robot satisfies these demands.

The robot’s corrosion-resistant stainless steel shell is designed according to German LFGB and US FDA food standards and also meets European CE certification, American UL certification and German TÜV safety function certification. The robot is protected against dust and moisture according to IP 67 protection class and can therefore be cleaned under high pressure and with alkaline or acidic cleaning agents.

KUKA DELTA robots are perfectly suited for pick-and-place applications in the high-speed sector, including the food industry.

Typical robotic applications include assembly and pick and place which, to satisfy today’s manufacturing demands require continuity, speed, and precision of execution as standard.