Onion peeler

12,000 onions per hour

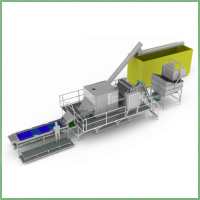

FAUP – Onions:

The onions are positioned vertically, by hand, or automatically using the Finis ‘Vision Technology’ onto the automatic feeding belt.

The onions are transported through the machine by means of a transportation chain with indexing plates. Through the process the product is notched, topped, tailed and finally peeled by an air blowing system. The perfectly peeled onions and their microbiological state ensure their long shelf-life. The FAUP is cost effective, as it requires minimum labour and little maintenance. It is also an easy machine to clean.

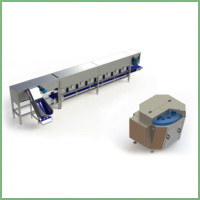

FAUP – Coring System:

The coring system removes the tops and tails of the onions, which ensures a higher yield. By incorporating an orientation unit into the fully automatic peeling line, results in no manpower being required.

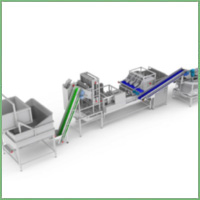

FAUP – Automatic Vision Infeed

The process entails; onions being fed into the orientation unit, above it, a camera continuously takes images, a computer then processes the images and locates the top and tail position of the onion. The orientation unit then starts to rotate the onion to the correct position. The eight units orientate up to eight onions in 1.5 seconds in total to feed the FAUP onion-peeling machine.